Gluing Wood Veneers With Contact Cement Q & A

Wood Veneer Factory Outlet.com

Q. What’s the best contact cement to use for gluing wood veneers?

A. We like the solvent based contact cements for gluing wood veneer sheets. We don’t like the water base contact cements.

Q. What is the best brand of contact cement for use on wood veneers?

A. Two of the best brands are Better Bond Titan Dx and Dural, but you may not be able to find these in your local home center.

Get the best solvent base contact cement that you can find. The higher the “solid”content (rubbers) the better. The extra money that you spend for the highest quality contact cement is well worth the cost.

Q. What surfaces can contact cement be applied to?

A. Contact cement can be applied to bare wood, and most contact cements can be used on painted and finished wood, metal, and some Formica and plastics, but: Check the instructions on the can.

Q. How do I prepare the surface when using contact cement?

A. If bare wood, just make sure that the surface is smooth, clean, and free of dirt or oil. This will hold true for most other surfaces, but check the instructions on the can.

Be aware that contact cement may not work with some plastic surfaces, as the solvent might attack the plastic. Do some testing when in doubt.

Q. What is better, contact cement in a can or contact cement in an aerosol spray?

A. Generally speaking, we recommend that you use the contact cement that comes in a can, that you apply by hand. We think that you get more coverage and a better glue layer, at less cost, with the contact cement that you apply by hand.

Q. How do I apply contact cement to my wood veneer and the substrate?

Q. How do I apply contact cement to my wood veneer and the substrate?

A. Use at least 2 coats of contact cement on the wood veneer and 2 coats on the substrate. Use a brush, roller, or a wide blade putty knife. Apply the coat as evenly and smoothly as you can. Work rapidly. Allow the first coat to dry before applying the second coat and so on.

Pay particular attention to the outer edges to make sure that you get good coverage of the contact cement.

Work in a well ventilated area that is at least 60 degrees F and isn’t humid.

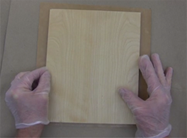

When the final coat is dry, wait no longer than 2 hours to proceed. Position the veneer in place and stick it down onto the substrate, applying pressure with your hands.

Once the veneer is in place, apply pressure with a 1” wide blunt piece of wood or a 1” wide wallpaper seam roller to help the contact cement to make a good bond.

Once the veneer is in place, apply pressure with a 1” wide blunt piece of wood or a 1” wide wallpaper seam roller to help the contact cement to make a good bond.

Do not use lacquer or penetrating finishes on paper backed veneers that have been glued down with contact cement. Reason: Lacquers and penetrating finishes can penetrate through the paper backed veneers and attack the contact cement. This warning does not apply to shellac finishes or varnishes. This warning does not apply to wood backed veneers which are impervious to bleed through of the finish to the glue layer.

Q. How do I get an exact fit of the veneer sheet to the substrate?

Q. How do I get an exact fit of the veneer sheet to the substrate?

A. Cut the veneer sheet to ½” larger on all sides than the substrate. Stick it down and trim off the excess with a razor knife. Inset panels are more tricky, as you have to cut the veneer to the exact size and use care when sticking the veneer in place.

Q. Does contact cement hold up over time?

A. Yes. The glue bond gets better with time.

Q. Are there any environments where the contact cement might not hold up?

A. The glue bond might be compromised by high heat, such as in an enclosed vehicle or exposure to a furnace vent, and by exposure to water or high humidity.

Q. Does contact cement work equally well on the paper backed veneer sheets and the wood backed veneer sheets?

A. Our customers use contact cement on paper backed veneers and wood backed veneers with good results. We think that the wood backed veneers provide an extra advantage because the wood backed veneer sheets are thicker and there is less chance for telegraphing unevenness of the glue layer.

Do not use lacquer or penetrating finishes on paper backed veneer sheets that have been glued down with contact cement. Reason: Lacquers and penetrating finishes can penetrate through the paper backed veneers and attack the contact cement. This warning does not apply to shellac finishes or varnishes. This warning does not apply to wood backed veneers which are impervious to bleed through of the finish to the glue layer.

Q. Can I use contact cement to glue wood veneers to exterior surfaces that are exposed to the elements?

A. Yes, but you are treading on untested ground and we don’t guarantee the results. Our customers have successfully used contact cement to glue wood veneer sheets on exterior doors and boats. Always apply a good, protective coat of finish to any veneer that is exposed to the elements. Specialized finishes, such as epoxies, are probably the best way to go.

We recommend wood backed veneers over paper backed veneers for areas that are exposed to the elements.

Note: We can supply our wood veneers with a phenolic back. This might be the best choice for exterior surfaces. Contact us for a quotation.

Bob Morgan, Pres.

Wood Veneer Factory Outlet.com