Wood Veneer Terminology Made Easy: “F/C”, “Q/C”, “Rift”, “Ribbon”, “Figured”, “Rotary” and “Tiger”

Wood Veneer Factory Outlet.com

Don’t get intimidated by wood veneer terms like “F/C”, Q/C”, “Rift”, etc, etc. – They’re nothing more than a way to describe how a wood veneer is sliced from a log.

These terms help you to know what the grain pattern of your veneer is going to look like.

Take a term like “F/C”, for example. Now, check out all of the photos on this website that show wood veneers that are “F/C”. Pretty soon you will see that “F/C” wood veneers have moving grains and cathedral grains.

Likewise, check out the photos that show “Q/C” veneers and pretty soon you will realize that the “Q/C” wood veneers have straight, parallel grain patterns.

Simple! You get what you see! Don’t get confused! Just look at the pictures!

If you want more info, here goes!

“F/C” – This is called Flat Cut. F/C is the most common slicing method for wood veneers. F/C produces moving grains and cathedral grains. Take a log, slice it length ways down the middle. Now, slice sheet after sheet from the face of the log. That’s called the flat cut method.

“F/C” – This is called Flat Cut. F/C is the most common slicing method for wood veneers. F/C produces moving grains and cathedral grains. Take a log, slice it length ways down the middle. Now, slice sheet after sheet from the face of the log. That’s called the flat cut method.

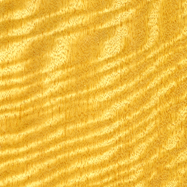

Here's Another F/C Grain. Notice how the grains are "moving grains", but they are not cathedral grains and they look differently than the F/C grain in the above picture.

Here's Another F/C Grain. Notice how the grains are "moving grains", but they are not cathedral grains and they look differently than the F/C grain in the above picture.

“Q/C” – This is called Quarter Cut. Take a log and cut it into 4 quarters or pie shaped wedges, lengthways down the length of the log. Slice your veneer sheets from the faces of the triangle wedges. That’s called quarter cut and it produces veneer sheets with comb gains and straight, parallel grains.

“Q/C” – This is called Quarter Cut. Take a log and cut it into 4 quarters or pie shaped wedges, lengthways down the length of the log. Slice your veneer sheets from the faces of the triangle wedges. That’s called quarter cut and it produces veneer sheets with comb gains and straight, parallel grains.

“Rift” – For practical purposes, rift is the same as quarter cut and it produces straight, parallel grains.

"Ribbon” – Just a particular name for quarter cut because when you slice some species, such as mahogany, using the quarter cut method, it produces straight, parallel grains that may look like ribbons.

"Ribbon” – Just a particular name for quarter cut because when you slice some species, such as mahogany, using the quarter cut method, it produces straight, parallel grains that may look like ribbons.

“Figured” – Figured describes how the light dances and glows off of the surface of a wood veneer. Some species produce figure and some species almost never produce figure. Even for the species that may produce figure, figure isn’t always present. Take a look at our photo of curly maple. That’s an example of a figured wood surface. See how the light glows off of the surface of the curly maple? That’s called figure.

“Curly”, “Fiddleback”, “Plum Pudding”, etc. – These are specific kinds of figures that exhibited in some wood veneers. They are Just a particular type of figure.

“Tiger” – As in “Tiger Oak” – Sometimes when an oak log is cut using the q/c or rift method, the grains produce prominent stripes, flecks, “corn flakes”, and “flakes” that accentuate the wood veneer surface. All of these are called “flake”, even though they may appear as stripes, flecks, corn flakes, etc.

“Tiger” – As in “Tiger Oak” – Sometimes when an oak log is cut using the q/c or rift method, the grains produce prominent stripes, flecks, “corn flakes”, and “flakes” that accentuate the wood veneer surface. All of these are called “flake”, even though they may appear as stripes, flecks, corn flakes, etc.

Flake patterns come from the medullary rays that are in the oak wood grains. Oftentimes, the patterns look like the stripes of a tiger and that is where the term “Tiger Oak” comes from.

Tiger oak veneer patterns can be very light and delicate, to flecs, flakes and very heavy, bold stripes.

“Rotary” – Take your veneer log and advance it against a stationary knife in a circular or rotating way, like toilet paper coming off the roll. This slicing method follows the annual rings of the log. It is a very cost effective way of producing wood veneers. The grain patterns may be somewhat similar to F/C grains, but they are generally very bold and wide or even “wild”.

“Rotary” – Take your veneer log and advance it against a stationary knife in a circular or rotating way, like toilet paper coming off the roll. This slicing method follows the annual rings of the log. It is a very cost effective way of producing wood veneers. The grain patterns may be somewhat similar to F/C grains, but they are generally very bold and wide or even “wild”.

Bob Morgan, Pres.

Wood Veneer Factory Outlet.com